Setting up accurate restaurant par levels is a cornerstone of proper inventory management.

If done right, par levels provide an effective framework for deciding the quantity of new inventory needed when placing orders for your restaurant.

The concept ensures that a restaurant always has enough inventory on hand to serve their customers, but not too much inventory that could lead to spoilage and waste.

This guide explains the meaning of par levels, how they’re calculated, and how restaurants can apply them to their businesses. Beyond that, this article covers how par levels are used in inventory management software to make a restaurant’s operations run more smoothly.

Restaurant Par Level Meaning

Par level refers to the minimum amount of inventory needed to meet customer demand until a restaurant’s next delivery.

When placing an order, restaurants use par levels to determine how much of each ingredient to order.

Par level is essentially a safety net that prevents restaurants from running out of necessary items. At the same time, it’s used to make sure a restaurant doesn’t have too much inventory that could lead to spoilage.

For example:

- If a restaurant’s par level for tomatoes is 6 cases, the restaurant would use this value to determine the quantity for their next order of tomatoes.

- Let’s say the restaurant currently has 3 cases of tomatoes on hand.

- On order day, they’d want to place an order for 3 new cases to reach a par level of 6 cases.

If the restaurant ordered only 2 cases of tomatoes, they’d probably run out and have to 86 the caprese salad. If they ordered 4 cases, they’d probably not use all of their tomatoes and a case would spoil.

Establishing the right par levels for stock items is a balancing act. It helps restaurants to have precisely the right amount of inventory on hand–not too much, and not too little.

Get the ultimate guide to inventory management software

- Inventory management software essentials

- What does inventory management software do?

- Signs you need this software

- How much money I can save & ROI

How to calculate restaurant par level

Calculating par levels is both an art and science.

It involves understanding your restaurant’s unique demand and seasonality patterns, supplier delivery schedules, and the shelf life of your products.

For calculating par levels, you’ll need to prepare the following information:

- Weekly inventory use for each item. This is the amount of each ingredient that you sell per week. This number can be found in your sales reports or your POS system.

- Safety stock for each item. “Safety stock” refers to a buffer amount for each ingredient that you’ll need. It’s a “just-in-case” measure. This lets you be safe in case there are any unexpected scenarios, such as late deliveries or an unexpected demand from customers for a certain ingredient. Safety stock is generally an extra 20-30% of weekly inventory usage.

- Frequency of deliveries per week for each item. This is the number of deliveries that you receive each week per each ingredient. For example, if you receive chicken breasts twice per week, then the frequency of deliveries is 2.

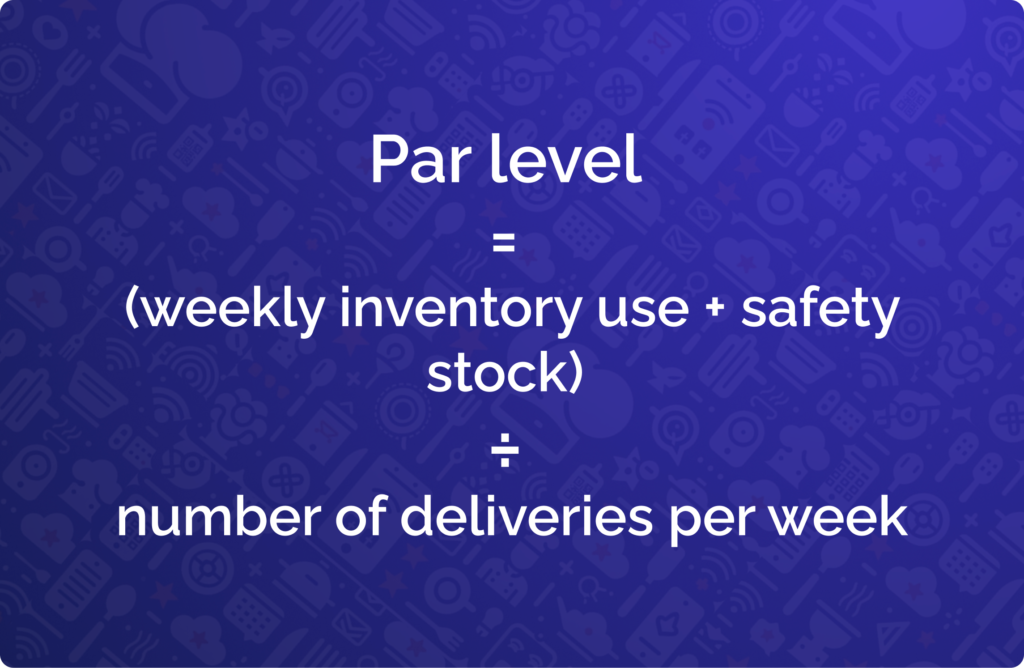

Par level Formula

Once you have the information from above, calulating par level is straightforward.

The formula for calculating restaurant par levels is:

Par level = (weekly inventory use + safety stock) / number of deliveries per week.

Par level calculation example

Let’s say we’re calculating par level for salmon pieces.

In this example, the restaurant uses 5 cases of salmon pieces per week. Salmon deliveries happen twice per week.

For the safety stock, we’ll use 20% as our benchmark. This means that our safety stock is 1 additional case (5 cases of weekly inventory use ✕ 20%).

Par level = (5 + 1 cases salmon) / 2 deliveries per week = 3.

Our par level is 3 cases of salmon.

This means that each time we order salmon, we should replenish our stock so that we have a total of 3 cases in inventory.

When inventory should exceed par level

Par levels should be used as a general guide for determining order size, but not be followed 100% of the time.

There are times when you will want to order more inventory than your par level.

Here are some cases where it makes sense for your inventory to exceed par level:

- Seasonality. A restaurant might be more busy in the summer than in the winter. Because of this, they’d be using more inventory during the summer and would need to increase their par levels during this time.

- Holidays. If you know your restaurant gets busy during certain holidays, you’ll want to increase your orders to above par levels during these times.

- Other big events. Similar to holidays, if you know there’s an event such as a convention happening in your city, then you’ll want to increase your order quantity during that time.

How often should par levels be recalculated

Determining par levels for your restaurant shouldn’t be a once-and-done project. Your par levels won’t be static over time.

As time goes by, it’s natural that demand for your ingredients will fluctuate. Perhaps you’ve adjusted the menu or your customers’ tastes are changing. Because of these changes, a restaurant should revisit their par levels often and make changes where they notice problems.

How to use par level when ordering new stock

Determining your restaurant’s par levels is the hard part.

Once you have your par levels, using them to determine order sizes is straightforward.

Whenever you do an order, you’ll want to reorder enough of each ingredient so that you’ll reach par level for those ingredients.

For example, if your par level for sour cream is 2 cases, and you have 1 case remaining on order day, you’ll want to order 1 new case to reach the par level of 2 cases.

How to use par level with inventory management software

Par levels are used in inventory management software to make the ordering process more efficient and more accurate.

This type of software can be hugely beneficial for improving a restaurant’s efficiency. We have a list of the top inventory management software solutions here.

In the sections below, we’ll cover how par levels are set up in the software and how the software uses them to make your orders run more smoothly.

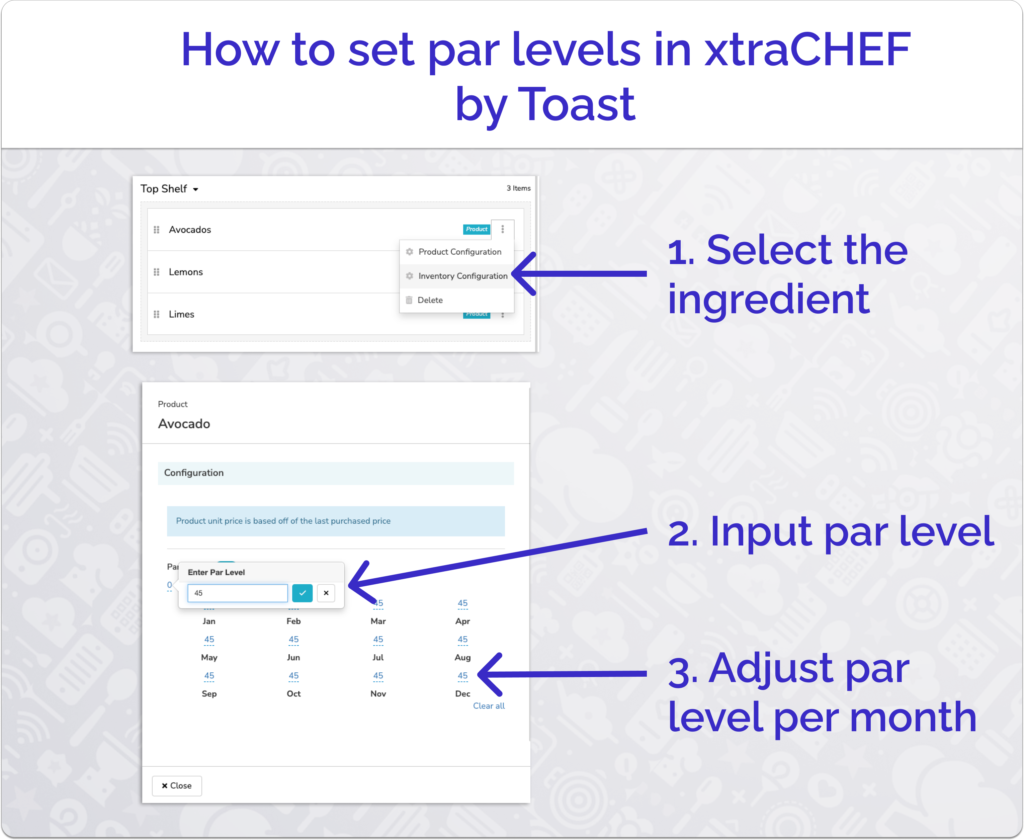

How to set up par levels in inventory software

xtraCHEF by Toast Reviews 2024: Details, Pricing, & FeaturesInventory management software lets you assign and save par levels for all of your ingredients.

You’ll usually enter this number manually, though some software providers such as Restaurant365 and others have special reports that suggest par levels for your ingredients.

Setting par levels inside the software is simple to do.

For example, in the xtraCHEF by Toast interface you’ll first locate an ingredient, then click into it, and then enter your par level. You can set the same par level for all months within the year, or you can adjust your pars for each month to account for seasonality.

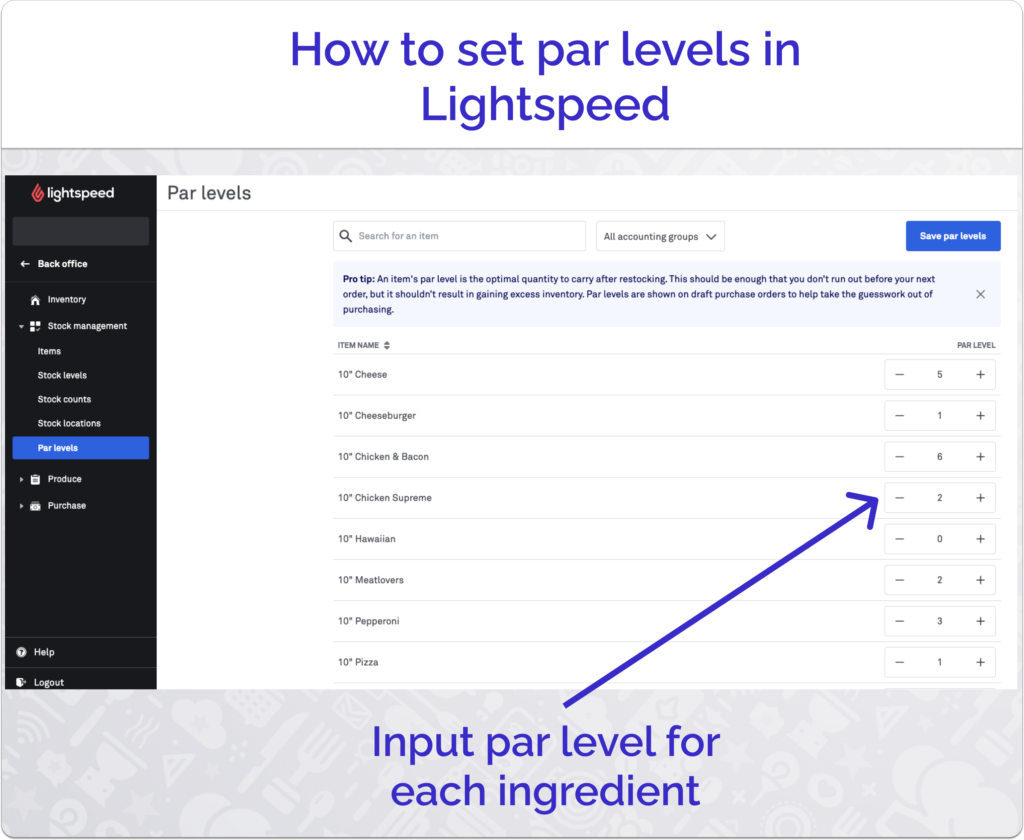

In Lightspeed, you’ll simply find a list of all your ingredients in the ‘Par Levels’ report and manually adjust the par level for each ingredient.

How par levels are used in the ordering process

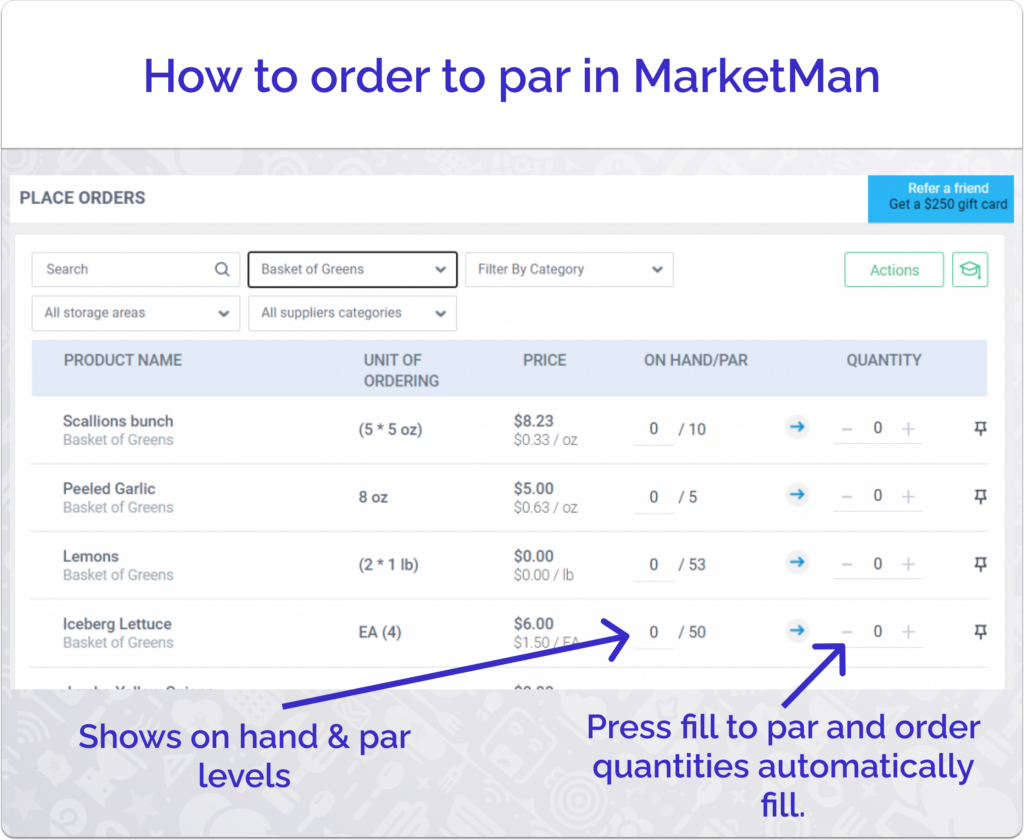

After you’ve entered par levels into the software, you can quickly place orders with suppliers by using an “order to par” or “fill to par” feature.

This type of feature subtracts what you have on hand from par levels, and automatically suggests an order quantity that would fill your stock back up to par.

Here’s a view of what this feature looks like for MarketMan.

Benefits of using par levels for inventory management

The main benefit of using par levels is that it makes a restaurant’s inventory management and ordering process a whole lot easier.

Without proper par levels, you and your staff are guesstimating how much of each ingredient you’ll need for the next order.

This can work a lot of the time. But anyone is bound to over- or under-estimate quantities needed at certain times, and this leads to waste or to 86ing menu items.

Par levels make the ordering process straightforward. You count what you have on hand, compare it to your par, and place the order.

Beyond making the ordering process more simple, other benefits of par level include:

- Helps you order the right amount of ingredients. Par levels enable you to make accurate orders and prevent overstocking or understocking.

- Waste control. By overstocking ingredients less often, a restaurant will have less waste.

- Healthy inventory turnover rate. Par levels make sure that you’re not overordering. This in turn means that a restaurant will use its inventory at a healthy rate.

- Saving money and improving profitability. Using inventory efficiently means saving money for your business.

- Improved cash flow. Since par levels encourage a healthy inventory turnover rate, you’ll be holding less inventory at any given moment. This means that your business’ cash won’t be tied up in inventory and you’ll have better cash flow.

Par level FAQs

What is the difference between par level and reorder point?

Par levels and reorder point are two inventory management concepts that help businesses keep an optimal stock level. They serve slightly different purposes and are used in different contexts. Par levels are generally more effective for restaurants since they’re dealing with inventory that has an expiration.

Par level is the ideal stock quantity a restaurant looks to maintain for each item to meet customer demand. It’s a target inventory level that triggers reordering when stock dips below this threshold. It makes sure a restaurant has just enough stock to satisfy demand, and helps to make sure that they’re not overordering.

Reorder point is a different method that uses a maximum quantity to determine order sizes. It accounts for lead time—the period between placing an order and its delivery—to ensure new stock arrives before running out. When inventory falls below a predetermined level, a large quantity is ordered so that lost sales can be prevented. This might work for certain non-perishable goods in a restaurant, but it’s generally not widely used in the industry.

Can par levels change over time, and how should they be adjusted?

Yes, par levels change over time. Demand for stock is constantly changing, whether due to seasonality, changes in the popularity of a restaurant, changes in customer tastes, changes to a menu, and so on.

Since change in demand is dynamic, restaurants should revisit par levels often and make adjustments when needed.

Restaurant owners can analyze their inventory usage data over time to determine how par levels should be adjusted. Historical data on sales numbers, spoilage levels, and stockouts can all provide clues as to when a par level needs to be changed.

Why are par levels important for restaurant operations?

Par levels are important for restaurant operations because they help make inventory counts and orders more efficient and accurate.

Establishing accurate par levels helps a restaurant reduce waste, prevents overordering and underordering, and most importantly has a direct impact on a restaurant’s bottom line.

What are the common challenges in maintaining accurate par levels?

Maintaining accurate par levels is a balance.

Some common challenges are:

- Accurately predicting demand, especially during seasonal changes or for new menu items.

- Dealing with delays in supplier delivery schedules which affect lead times.

- Managing the balance between minimizing waste and preventing stockouts.

- Keeping inventory data up-to-date.

How do specials or promotions impact restaurant par levels?

Specials and promotions increase temporary demand for certain ingredients, which means that a restaurant will have to make adjustments to par levels to accommodate the spike in usage.

When planning promotions, a restaurant would want to forecast the expected increase in demand before the promotion begins, and adjust their order quantities based on the forecast.

How does supplier reliability affect par level calculations?

The reliability of a restaurant’s supplier deliveries affects the restaurant’s par level calculations.

If a supplier is consistently reliable, this gives the restaurant more confidence that the supplier will deliver every day that they commit to. In this case, it’s possible for the restaurant to keep a lower safety stock and maintain par levels closer to actual usage rates. This reduces inventory costs and limits waste.

However, with less reliable suppliers who sometimes have delivery delays, restaurants must increase their safety stock to mitigate the risk of stockouts. This leads to higher par levels, which leads to higher inventory on hand, which could lead to increased waste.

What are the financial implications of not maintaining proper par levels?

Not maintaining accurate par levels can have negative financial implications for a restaurant, including lost sales from stockouts and customer dissatisfaction. Overstocking ingredients can result in higher levels of spoilage.

Accurate par levels help a restaurant optimize their inventory costs, reduce waste, and improve customer satisfaction by always having the right items available for their customers. These all lead to higher profits.

Are there industry standards for par levels, or are they restaurant-specific?

There are no one-size-fits-all industry standards for par levels. Par levels are highly restaurant-specific.

Each restaurant’s menu, customer demand, and supplier relationships influence its ideal par levels.

Effective par level management requires customization based on the restaurant’s unique operations, sales data, and experiences.

Restaurants should regularly review and adjust par levels based on changing demand levels within their restaurant.